It is clear from Table 1 that the series series counterflow arrangement yields the lowest full-load chiller power about 14 lower than the parallelparallel configuration. Some chille rs can tolerate flow-rate variationsas much as 50.

Improving System Efficiency Using Series Counterflow Piping Strategy 2021 01 14 Process Cooling

Dual Circuit Series Counter-flow Chillers Overview The WCT chiller has a single evaporator and a condenser.

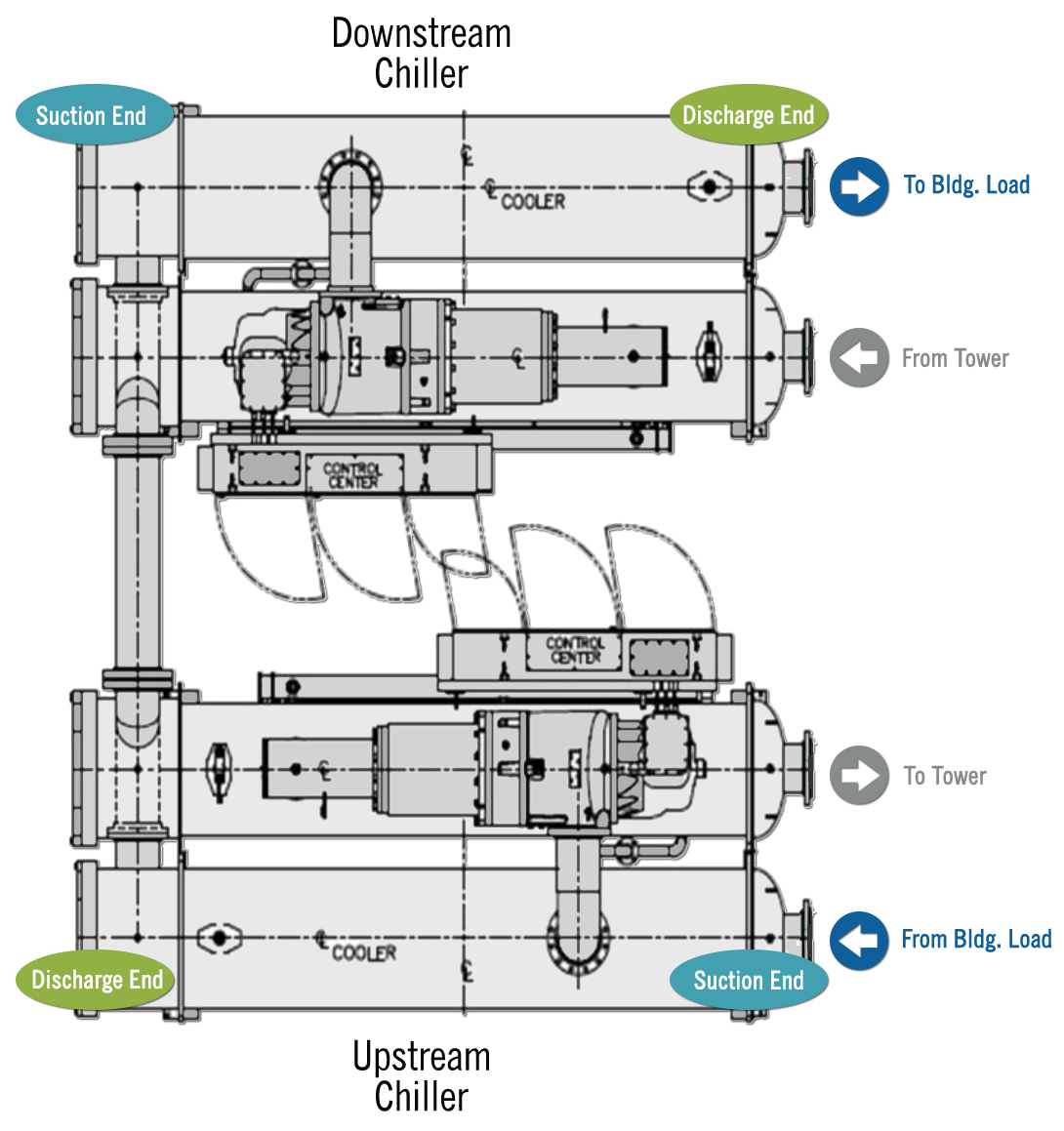

. Configuring water-cooled chiller plants in a series counterflow SCF arrangement splits the lift between two machines to enhance the operating efficiency of the plant. A two chiller series counterflow arrangement provides an associated reduction in effective compressor lift. The dramatic reduction in chiller power oc-curs because the upstream chiller in the seriesseries counterflow arrangement operates at a higher chilled water.

Each evaporator and condenser shell contains two separate refrigerant circuits for each of the two compressors and economizers on the chiller. This document will evaluate the impact of SCF on efficiency while keeping in mind what it requires on the building controls side as well as plant design piping arrangement. 4 Chiller System Design and Control SYS-APM001-EN Primary System Components Some chiller controls can accommodate very little flow variation during machine operation2 Other more sophisticated chiller controls allow some flow variation.

Series counterflow condenser water improves the chiller performance as explained in the Series counterflow chiller example. Pump selection crucial and avoid oversizing as they. Browse discover thousands of brands.

Some chiller controls can accommodate very little flow variation during machine operation2 Other more sophisticated chiller controls allow some flow variation. Chillers are piped in series counterflow if one surges it is likely that the adjacent centrifugal chiller will surge as well. Series counter flow chillers can be 5 to 7 more efficient than a single chiller at design conditions and save up to 20 of chiller energy annually.

This document will be directed toward water-cooled centrifugal chillers predominately but is. The cooled water or waterglycol mix is then channeled through the lumen of the larger tube to run in an opposite direction to the flow of wort and hence cool the brew. Advanced high efficiency two-stage compressor design specifically for HFC-134a.

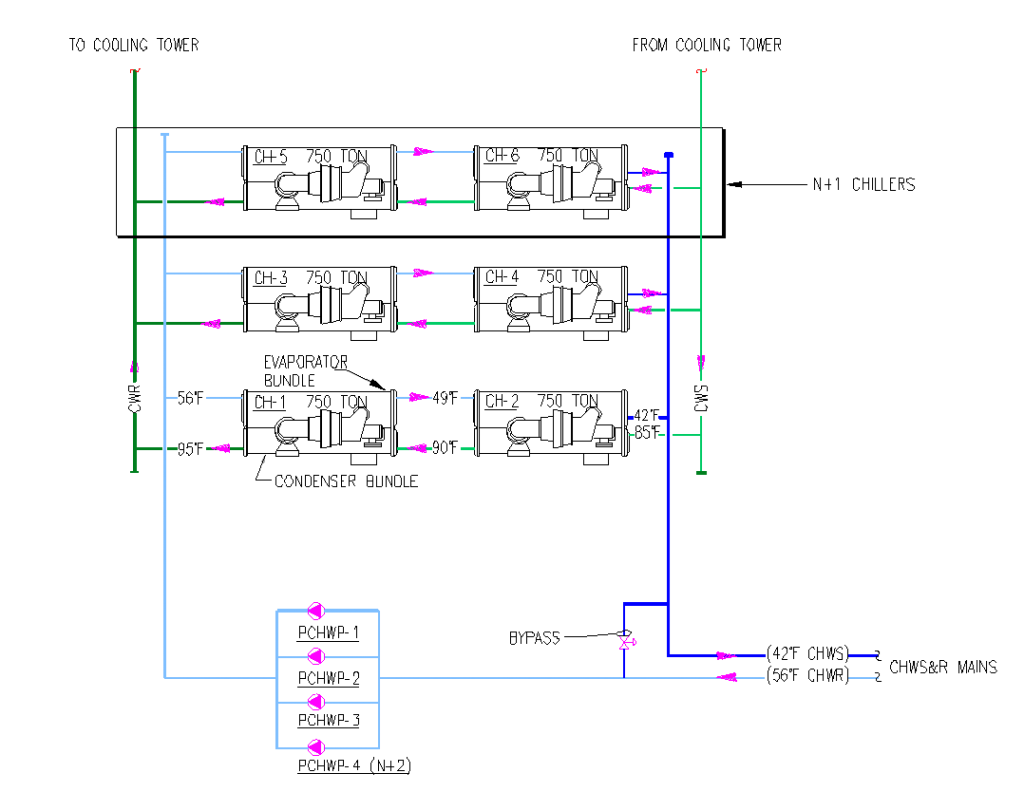

Series Counterflow Chiller Arrangement Variable Primary Only. In systems with constant flow through the chillers evaporators designers often specify maximum acceptable pressure drops. Use of a chiller piping strategy called Series Counter-Flow SCF.

The design flow pressure drop through a pair of chillers in series is likely to be much higher than what is considered acceptable in a parallel system. Chillers are often the single largest electricity users in a building. Chiller full load efficiency ratings are usually given in the form of.

This document evaluates the impact of SCF on efficiency while keeping in mind what it requires on the building controls side as well as plant design piping arrangement. 19XR Two-stage Centrifugal Chiller Series Counter Flow Application Industry-leading Efficiency 19XR chillers can achieve up to 66 full load COP R and 75 IPLVIP without VFD or 110 IPLVIP with VFD at AHRI conditions. Two 525 ton chillers in Series Counter Flow One chiller meets 525 ton critical load Running redundancy Variable primary pumping system.

Especially New Technology Chillers Define Series Counter-Flow DOAS Chilled Beams Compare ASHRAE 901-2004 Baseline Building vs. McQuay has the ability to design and manufacture special centrifugal compressor chillers with unique design characteristics such as completely packaged indoor or outdoor chiller plants series counterflow chillers and others. System Power for VPF with Series Chillers.

Series-Series-Series Chillers or Series-Series-Counterflow Chillers CHILLED WATER RETURN CHILLED WATER SUPPLY 55F 451F 37 F 989F 913F 85F EVEN Further Reduced lift EVEN MORE savings. Heat elimination using a counterflow chiller is achieved using a series of concentric tubes. In a SCF configuration the chiller making the coldest chilled water also gets the coldest condenser water.

951F 881F 500 F410 951 o F 451 oF 50oF 989 o F 50 oF 913 o F 41 oF 881 o F 37 oF 50oF 51oF 489oF 19 Reduction. Chillers allows the design engineer to produce chilled water in a central building location or even on the roof and distribute the water economically and without the. A 1000 ton chiller has a motor rated at 700 hp.

Consult you local McQuay sales office. Each circuit is isolated from each other by a welded tube sheet in the middle of the vessel. Figure 6 below illustrates this domino effect of surging that is characteristic of centrifugal chillers.

Maximizing Infrastructure Minimizing Inefficiencies In series-series arrangements both the evaporator and condenser circuits are in series and in countercurrent flow so that the downstream chiller producing the coldest chilled water. Some chillers can tolerate flow-rate variations of as much as 30 percent per minute or greater while others can only tolerate up to 2 percent per minute. 60 44 Evaporator 85 30 gpm per ton in Condenser Energy Efficiency a priority Any one chiller can provide 75 capacity.

Improving the chiller performance has immediate benefit to the building operating cost. A smaller tube made of copper situated within a larger external tube is used to convey the hot wort. In case one if the upstream chiller surges as a result of a rapid increase in ECdWT from 85F to 88F.

Read customer reviews find best sellers. Pumping energy can be higher than parallel arrangement. Figure 41 - Series Counterflow System Design.

Now Variable Primary Only Series Counterflow This configuration improves overall chiller efficiency by reducing the lift on the compressor. Industrial Design Positive displacement screw compressor cannot surge Quickly adapts to system changes 134a positive pressure no. One of the many system modifications that has the ability to improve efficiency greatly is the use of a chiller piping strategy called Series Counter-Flow SCF.

The Benefits Of A Series Counterflow Chiller Arrangement Tlc Engineering Solutions

How Do I Model Series Counterflow Chillers In Trace 700

Improving System Efficiency Using Series Counterflow Piping Strategy 2021 01 14 Process Cooling

Pdf Series Series Counterflow For Central Chilled Water Plants Semantic Scholar

Chiller Series Counterflow Carrier Commercial Systems North America

Improving System Efficiency Using Series Counterflow Piping Strategy 2021 01 14 Process Cooling

Pdf Series Series Counterflow For Central Chilled Water Plants Semantic Scholar

0 comments

Post a Comment